How To Select Suitable Axle For HOWO Truck?

18 Jun 2020

When referring to the rear axle, nobody seems to deny its importance apart from the engine among truck spare parts. The rear axle plays significant roles in load bearing, driving and braking. Choosing a matching axle can not only make trucks have a high performance, but also help drivers reduce the fuel consumption. In conclusion, it is critical for drivers to get to know the axle.

The mainstream axle for HOWO truck was ST16, HC16, AC16 and MCY series, ST16 and HC16 was developed base on Steyr technology, AC16 was product acoordingly Benz technology and MCY series axle was cooperated with MAN. Among those axles, ST16 and HC16 was very popular to assembled on HOWO trucks for exporting. Because:

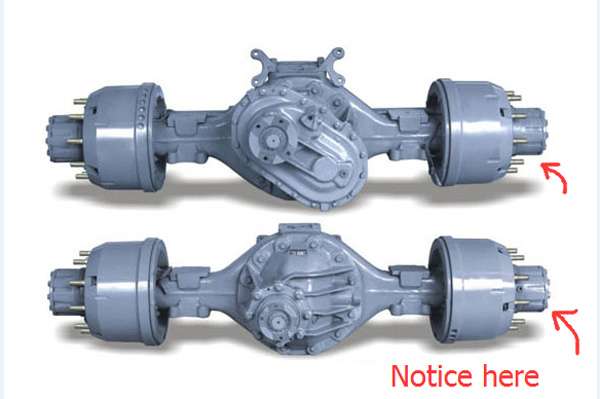

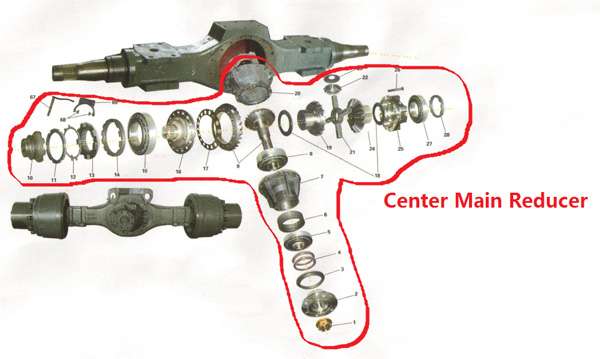

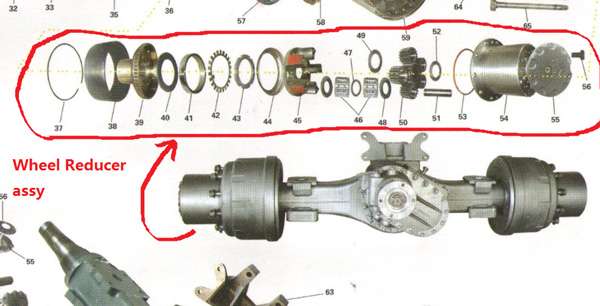

1. They were all assembled by DOUBLE reducer, MAIN reducer + wheel reducer, as there is wheel reducer, so the bever gear and crown gear measurement was minified, increase ground clearance.

2. Strengthen the section of axle housing, use punching welding steel and casting steel, improve the axle load.

3. The single rated axle load was 16000KG.

4. The steyr axle parts has HIGH commonality, since Steyr axle was assembled widely on the Chinese brand truck, like HANDE 13Ton axle of Shacman truck, LB300 axle on FAW truck, also assembled on Genlyon truck.

Let me introduce this two axles:

1. ST16 Double Reducer Driving Axle

And the nameplate was PINK color:

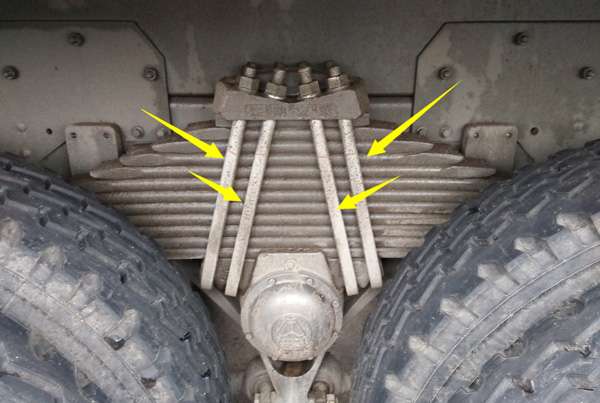

AND the U bolt for rear leaf spring was 2 pcs:

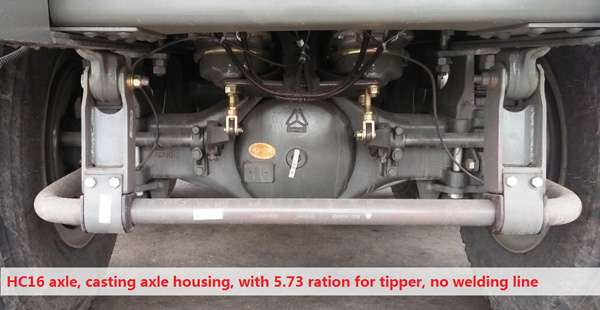

2. HC16 Double Reducer Driving Axle:

The nameplate was YELLOW color:

And the U bolts for rear lear spring was 4 pcs:

3. Contrast punching welding and casting steel:

Content | Production efficiency | Environment | Variant ability | Machining defects | Weight | Manitence | Cost |

Punching welding | High can be mass production | Eco-frindly | Easy to Twist compare casting axle housing | Can avoid the defects easily | Lighter than casting axle | Complicated | Higher |

Casting steel | Lower | Environmental pollution | Hard | Defect: Sand holes and Slag | Heavy | Easily repair, simple struction | Lower |

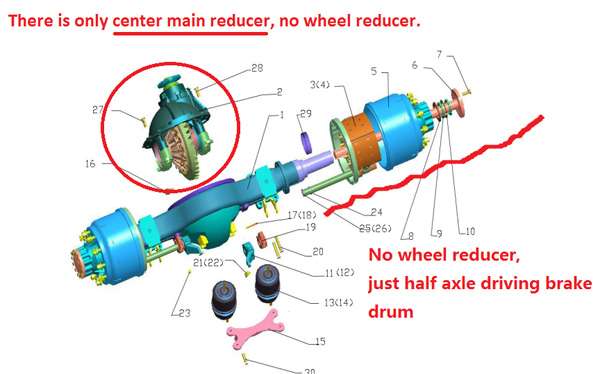

4. Single reducer axle VS double reducer axle

Contect | Fuel Consumption | Torque capacity | Ground clearance | Weight | Manitence | Application | Cost |

Single main Reducer | Lower | Less, lower capacity for overloading | Lower, suitable for good road | Light | Easy Low cost | Prime tractor | Cheaper |

Double Reducer | Higher | High capcaity for overloading | Higher, suitable for bad road conditions | 5% heavier than single reducer | Complicated Higher cost | Heavy duty tipper | Higher |

Contruction and appearance of Single reducer axle:

Contruction and appearance of Double reducer axle:

According above presentation, have you learnt more about the axle? If there is any axle parts inquiry, welcome to contact me—— Qingdao Size The Future Automobile Sales Co., LTD.